PRODUCTS

AAC, Bricks & Cement

ACON AAC BLOCK

Download Catalogue

THICKNESS : 100MM, 125MM, 150MM, 200MM

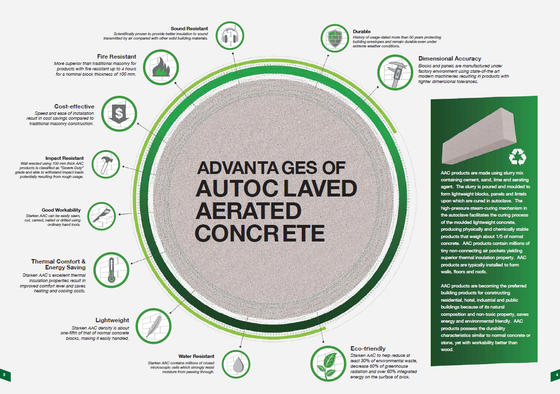

Autoclaved Aerated Concrete (AAC) and also known as Autoclaved Lightweight Concrete, (ALC), is gaining its popularity in the building and construction industries in Malaysia. The finished product is only one fifth the weight of regular concrete and has good insulation, acoustic and fire resistance properties. Alam-Con AAC is designed for walls applications and is available in various sizes requirements.

The lightweight blocks manufactured are AAC blocks with sizes ranging from 600 x 200 x 100, 600 x 200 x 125, 600 x 200 x 150 and 600 x 200 x 200 (mm). These AAC blocks are good savings and efficient for construction in individual houses, link houses, condominiums, hotels, hospitals, shopping complexes, schools, shoplots and also industrial buildings. Alam-Con blocks brand name is ACON. Complying with BS EN 771-4 : 2003 and

BS 476 : PART 22 : 1987

ACON AAC increases speed of installation leading to efficient manpower employed, the AAC products dimensions are accurate, reduces wastage creating a better and cleaner working environment.

Cost Savings, with lower density and larger dimension, it can reduce the building dead load and subsequently on the foundation and structure cost as well as labour cost.

STARKEN AAC BLOCK

Download Catalogue

AAC SIZE : 600mm x 200mm x 100mm

AAC Applications:

- General internal & external walls

- Party, compartment & separating walls

- Acoustic & fire-rated walls

Starken Standard AAC Blocks offer a fast, convenient and versatile solution for most walling requirements. Each AAC lightweight block is equivalent to 7 pieces of common brick.

Starken AAC blocks are easy to work with and can be cut to size with a tungsten carbide-tipped handsaw. This allows maximum flexibility and minimizes wastage.

CASTLE brochure

CASTLE CEMENT

Bag cement

Castle

Castle is a mainstay of our ECOCem product line. Made with 30% to 40% lower CO₂ emissions¹, it is a certified Singapore Green Label cement. Its excellent versatility makes it suitable for all general-purpose applications, such as bricklaying, screeding, and concreting applications. Castle has excellent workability and is easy to mix.

ECOCem is our range of low carbon cement to help Malaysia build sustainably. It is produced with lower CO₂ emissions and contains repurposed materials. ECOCem is our contribution to making the low carbon circular economy a reality.

¹emissions per tonne of cement vs OPC

Certifications

MS EN 197-1:2014 CEM II / B-L 32.5N

Singapore Green Label

Key Benefits

Eco-friendly product

Superior workability

Quality consistency

Good cohesiveness

Easy to mix

Applications

Suitable for all general-purpose applications

WALLCEM CEMENT

Bag cement

Wallcem

Wallcem is another member of our ECOCem product range. It is formulated to give better performance in plastering applications in terms of water retention, cohesiveness, and workability of the mortar. Its stronger adhesion gives walls a better finishing, which makes it ideal for internal and external plastering works. Wallcem is produced with 30% to 40% lower CO₂ emissions¹.

ECOCem is our range of low carbon cement to help Malaysia build sustainably. It is produced with lower CO₂ emissions and contains repurposed materials. ECOCem is our contribution to making the low carbon circular economy a reality.

¹emissions per tonne of cement vs OPC

Certifications

Masonry Cement 22.5X

Key Benefits

Eco-friendly product

Excellent workability

Achieves better finishing

Quality consistency

Easy to mix and apply

Applications

Suitable for internal and external plastering works

CONCRETE ROOF TILES

Monier Elabana Roof System has been protecting homes from the harsh tropical weather in Malaysia for over 30 years.

Monier Elabana Tropical roof system has bridged all elements of World Class Industrial Excellence in roofing technology, superior quality and cost efficiency.

Length 420 mm

Width 330 mm

Maximum Pitch 90 °

Minimum Pitch 17.5 °

Laying Pattern Straight Bond / Cross Bond

Maximum Batten Spacing 345 mm

Minimum Batten Spacing 295 mm

Tile Coverage Per Sqm At Minimum Batten Spacing 9.7 pcs

Tiles per Pallet 318

Net Weight 4.2 kg

Gauge 295 - 345 mm

Minimum Overlap 75 mm

Kinson Marketing Sdn. Bhd.

No. 97A, Jalan Bendahara, 31650, Ipoh, Perak, Malaysia

© 2024

All Rights Reserved | Kinson Marketing Sdn. Bhd.

Designed by Trinity42